In the commercial construction sector, efficiency, precision, and cost management are critical to project success. Traditional formwork methods such as timber and steel have long been used, but the increasing demand for faster and more sustainable building solutions has shifted attention to aluminium formwork systems.

Built from durable aluminium alloy profiles, these systems are designed for repeated use and can be easily adapted to different project requirements. For commercial contractors aiming to cut costs while maintaining high quality, the aluminium formwork system offers clear advantages.

What is Aluminium Formwork?

Aluminium formwork is a pre-fabricated system designed to shape and support cast-in-place concrete structures. Unlike timber, which wears out quickly, or steel, which can be heavy and cumbersome, aluminium alloy combines strength with lightweight properties. These profiles are precision-machined and welded to create panels and components that can be freely assembled according to specific structural designs.

Thanks to its modular nature, aluminium formwork can be easily assembled and disassembled. This makes it ideal for large-scale commercial construction projects that require fast construction cycles. In fact, with aluminium formwork, one floor can be completed in just 3 to 5 days, significantly shortening the overall construction period.

Its precise design and assembly capability also ensure high-quality concrete surfaces for walls, slabs, and columns, often eliminating the need for additional plastering. For modern commercial buildings, aluminium formwork offers both efficiency and superior finish, making it a preferred choice in contemporary construction.

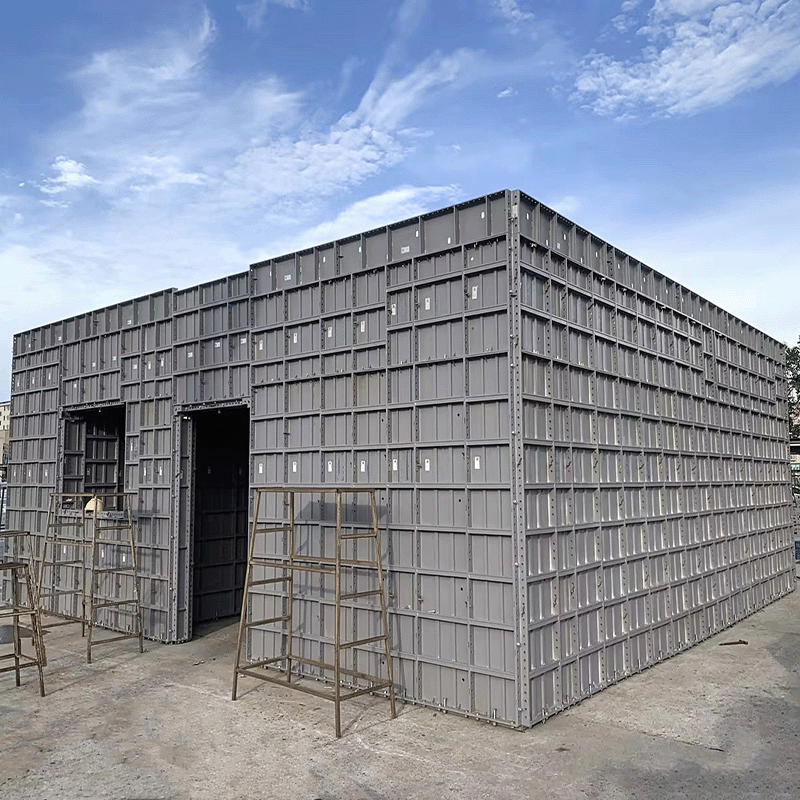

Aluminium Formwork System

Key Advantages of Aluminium Formwork Systems

1. Superior Forming Quality

One of the primary benefits of aluminium formwork systems is the excellent forming effect. Large single panels reduce patchwork, and the high precision of the components ensures verticality and flatness within 5 mm. This allows commercial buildings to easily reach the quality standards of fair-faced concrete construction - a true plaster-free finish, both inside and out.

With such precise and smooth surfaces, finishing becomes much more efficient. High-quality concrete eliminates the need for additional plastering or surface treatments, saving both time and cost. Aluminium formwork’s strong bearing capacity also ensures consistent results, even for large-scale projects.

2. Reduced Construction Costs

Aluminium formwork systems can significantly lower construction costs. Their high reuse rate and efficient assembly reduce labor expenses and minimize reliance on heavy equipment such as cranes.

Additional savings come from eliminating plastering and reducing decoration costs, as the finished concrete surfaces are ready for final use. Moreover, aluminium formwork retains high scrap value, allowing construction companies to recover some investment at the end of the project.

3. Faster Construction Speed

Time is a critical factor in commercial construction, and aluminium formwork excels in this area. Lightweight aluminium formwork panels can be easily carried and assembled by workers without heavy machinery.

The modular nature of aluminium formwork simplifies assembly and disassembly, allowing construction teams to work like building blocks. One floor can be poured in just a few days, accelerating overall project timelines and improving efficiency.

Aluminium Formwork Installation for Villas

4. Enhanced Safety on Site

Safety is a major concern in any construction project. Aluminium formwork offers a high level of stability due to its strong, deformation-resistant material. Once assembled, the system forms a stable frame that reduces the risk of accidents.

The need for cranes or aerial work is minimized, decreasing the likelihood of falls and injuries. Lightweight components also make manual handling safer, contributing to an overall safer working environment.

5. Environmentally Friendly Solution

Sustainability has become a key focus in global construction. Aluminium formwork systems support this shift by offering:

- Long service life – panels can be reused up to 300 times.

- Recyclability – once the panels reach the end of their life cycle, the aluminium material can be recycled without waste.

- Reduced debris – less timber use means less construction waste, supporting cleaner sites and environmental responsibility.

By lowering waste and promoting recycling, aluminium formwork aligns with green building standards, an increasingly important requirement for commercial developments.

GETO Aluminium Formwork Systems

In modern commercial construction, efficiency, quality, and sustainability are key factors for project success. GETO, a professional manufacturer of aluminium formwork and scaffolding solutions, provides high-quality systems designed to optimize construction processes worldwide. GETO offers two main aluminium formwork systems tailored to different project needs:

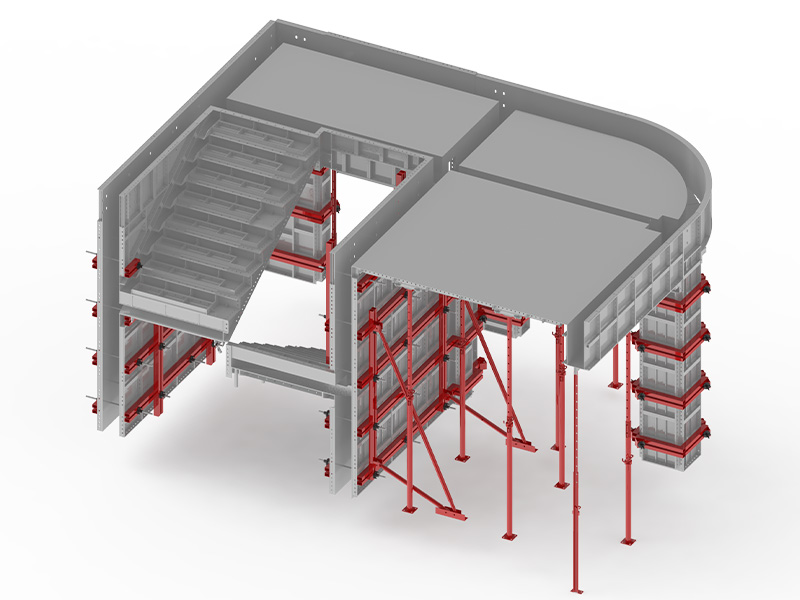

Aluminium Formwork Tie-Rod System

The tie-rod system delivers smooth forming effects and is ideal for refurbishment projects or walls with thicknesses greater than 400mm. It provides a strong and stable framework that can adapt to complex structures while ensuring high-quality concrete surfaces.

Aluminium Formwork Tie-Rod System

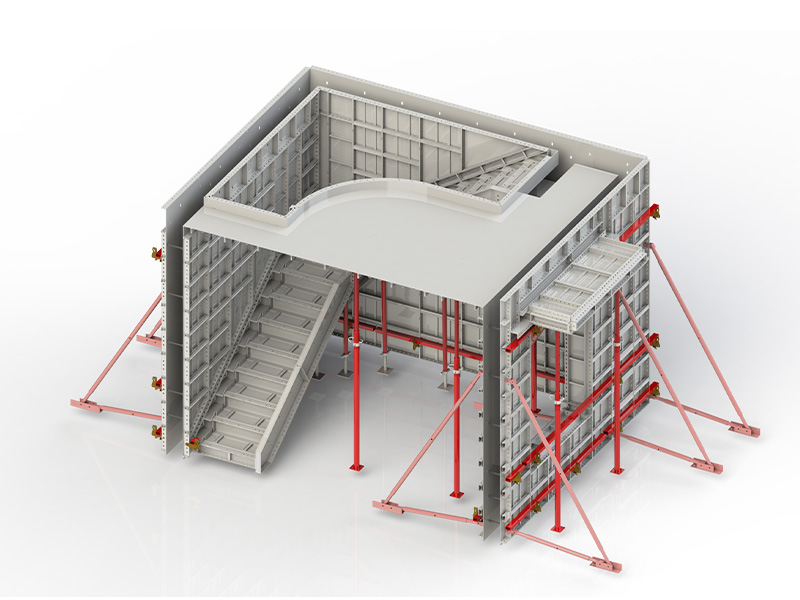

Aluminium Formwork Flat-Tie System

The flat-tie system simplifies assembly, eliminates the need for drilling, and uses fewer installation accessories. Its design aligns with workers’ habits across different regions, improving efficiency while delivering excellent vertical casting and reducing labor intensity.

Aluminium Formwork Flat-Tie System

Choosing the right system depends on project requirements. Whether you prioritize strength, adaptability, or fast assembly, GETO aluminium formwork systems meet diverse construction demands while providing safety, superior concrete surface quality, and environmental sustainability.

Applications of Aluminium Formwork in Commercial Construction

Aluminium formwork systems are widely used in various types of commercial projects, including:

- Residential and office buildings: Accelerate floor construction, improve concrete surface quality, and minimize finishing work.

- Hotels and resorts: Reduce labor costs and shorten construction timelines without compromising structural integrity.

- Educational and healthcare facilities: Provide safe, precise, and environmentally friendly construction methods for large-scale projects.

- High-rise buildings: Support heavy loads and complex designs while maintaining rapid construction speed.

The Long-Term Value of Aluminium Formwork in Modern Construction

Commercial construction increasingly demands methods that combine speed, safety, and cost-efficiency. Aluminium formwork systems meet these needs while offering reusable, environmentally conscious solutions. The precision, stability, and modularity of these systems improve both project quality and efficiency.

Investing in aluminium formwork also provides long-term benefits. Reduced labor and equipment costs, combined with rapid floor construction, can lead to faster project completion and better return on investment.

Aluminium Formwork For High-Rise Buildings

Conclusion

For commercial projects worldwide, adopting aluminium formwork is a strategic decision that delivers both immediate and long-term value. By choosing aluminium formwork systems, construction companies can streamline workflows, enhance concrete surface quality, and achieve more sustainable building practices.

Whether it’s high-rise developments, commercial complexes, or renovation projects, aluminium formwork systems remain a practical and efficient choice for modern construction needs. Ready to take your next project to the next level? Contact GETO today to explore custom aluminium formwork solutions designed to help you build smarter, faster, and more sustainably.