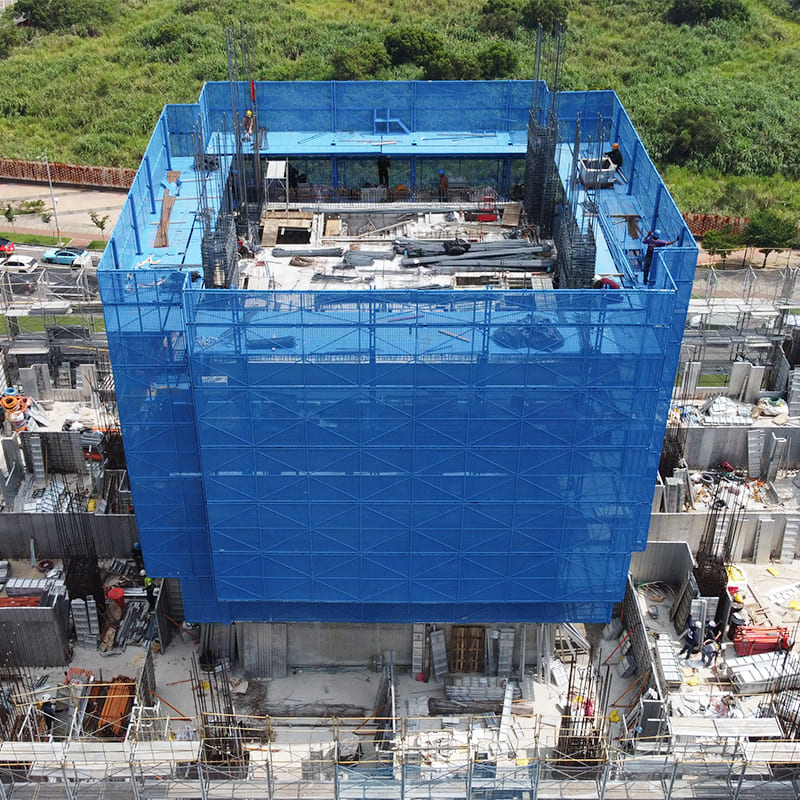

High-rise construction projects demand efficiency, safety, and precision. The automatic hydraulic climbing formwork system has emerged as a reliable solution for complex structures, offering significant advantages over traditional formwork methods. GETO’s GTP100 automatic hydraulic climbing formwork system exemplifies these benefits, combining innovative design with practical functionality for large-scale construction projects.

What is Automatic Hydraulic Climbing Formwork?

An automatic hydraulic climbing formwork system is a construction technique that integrates formwork, climbing brackets, platform systems, and suspension brackets directly with the concrete structure. Once concrete reaches the required strength and the formwork is stripped off, hydraulic cylinders drive the climbing brackets along the guided climbing rails to the next level. This cycle repeats as construction progresses, allowing continuous and safe vertical advancement.

The formwork is integrated with the climbing brackets, moving together with the traveling units. This integration significantly reduces labor requirements and ensures an enclosed construction environment, minimizing risks of falls from heights.

GETO’s climbing formwork is suitable for a variety of large structures, including internal shafts, facade walls, core walls, shear walls, massive columns, bridge towers, signal towers, silos, etc. Its versatility makes it a reliable choice for projects requiring both vertical precision and operational efficiency.

Automatic Hydraulic Climbing Formwork System

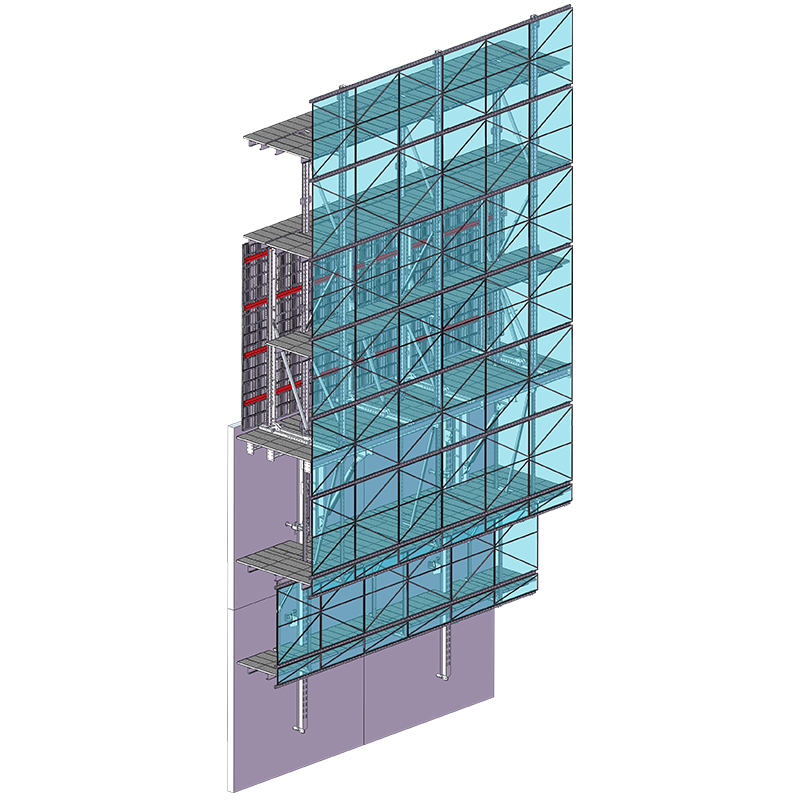

Key Components of the GETO GTP100 Climbing Formwork System

This well-designed climbing formwork system relies on a combination of structural components, all engineered for safety, efficiency, and adaptability:

1. Climbing System

Climbing rail – guides the brackets during ascent

Hydraulic cylinder & lifting mechanism – powers vertical movement

Climbing head, vertical profile, main horizontal profile – provide structural support

Diagonal bracing spindle strut & supporting carriage – enhance stability during climbing

2. Main Platform Beam

H200 beam and 20# U channel beam provide a sturdy base for operational platforms.

3. Lower Platform Hanging Bracket

Vertical and horizontal profiles at multiple levels (-1F, -2F)

Diagonal bracing ensures stable load distribution

4. Formwork Traveling Unit

Vertical walers, horizontal profiles, and diagonal bracing spindle struts maintain formwork alignment during climbing

5. Anchoring System

Includes attachment supports, embedded climbing cones, M36 screws, stop anchors, and sealing sleeves to secure the system firmly to the structure

6. Upper Platform Bracket

Vertical and horizontal profiles, diagonal bracing, and flip platform horizontal profiles support operational activities at the top

These components work together to create a self-contained climbing formwork system that reduces reliance on cranes, scaffolding, or repetitive alignment processes.

Automatic Hydraulic Climbing Formwork

Advantages of GETO Automatic Hydraulic Climbing Formwork

1. Safety First

Safety is a top priority in high-rise construction, and GETO’s automatic hydraulic climbing formwork system integrates multiple features to protect workers:

Fully steel-hardened structure: The climbing brackets, platforms, and protective screens are made of robust steel, improving overall structural stability and fire resistance.

Enclosed protective screening: The climbing brackets are equipped with fully enclosed steel shields, preventing falls and reducing the risk of accidents from falling objects.

Formwork retraction gear: The system includes a retraction mechanism for the formwork traveling units, reducing the risk of accidents caused by sudden movements and preventing concrete grout leakage.

Synchronized operation: Hydraulic climbing ensures vertical and inclined movements are smooth and synchronous, minimizing sudden jolts that could endanger workers.

Integrated rebar installation platforms: These platforms move in sync with the climbing brackets, allowing safe, continuous access for steel reinforcement installation without additional scaffolding.

Reduced need for scaffolding and cranes: By enabling self-climbing with integrated formwork, workers are less exposed to heights and moving equipment.

2. High Cost Efficiency

GETO’s automatic hydraulic climbing formwork is engineered to save both time and resources:

Reduced labor costs: The fully integrated climbing system reduces manual labor, as the formwork moves automatically with the brackets.

Minimized formwork damage: Continuous climbing reduces repetitive assembly and disassembly, extending the lifespan of formwork components.

Efficient material usage: Automatic climbing formwork platforms and brackets reduce the need for extra scaffolding, temporary supports, or additional safety barriers.

Shorter project timelines: Faster climbing and repetitive cycles allow construction to proceed quickly, leading to significant overall cost savings.

GETO Automatic Hydraulic Climbing Formwork

3. Convenience and Flexibility

Ease of installation, operation, and maintenance makes GETO’s climbing formwork system highly practical:

Modular design: Protective screens, platforms, and brackets are modular, allowing quick assembly, disassembly, and transportation.

Self-climbing formwork: The formwork moves with the climbing brackets, enabling direct adjustments, cleaning, and minor repairs without crane assistance.

Integral or separate climbing: Brackets can climb as a single unit or individually, adapting to project-specific structural or site conditions.

Adjustable platforms: Multiple operational platforms allow workers to perform concrete finishing, rebar installation, and inspection without additional scaffolding.

Weather-adaptable design: Hydraulic climbing systems can adjust to minor inclinations or slight wind variations, providing safer and more reliable operation.

4. Improved Construction Quality

GETO’s climbing formwork system not only improves safety and efficiency but also enhances the quality of the finished structure:

Precise alignment: Hydraulic climbing ensures accurate vertical and horizontal positioning of formwork, reducing deviations in walls and cores.

Smooth concrete surfaces: Integrated platforms and formwork allow better control of concrete pouring and finishing, minimizing surface defects.

Consistent structural integrity: Synchronization of climbing brackets and formwork reduces stress points and ensures even load distribution throughout the structure.

5. Environmental and Site Benefits

Automatic hydraulic climbing formwork systems not only improve construction efficiency and safety but also offer significant environmental and site management benefits.

Reduced construction footprint: By eliminating extensive scaffolding, the system decreases material waste and site clutter.

Safer work environment: Enclosed platforms and self-climbing mechanisms limit worker exposure to height hazards and falling debris.

Sustainable operation: Fewer crane operations and less manual labor lead to reduced energy consumption on-site.

GETO Hydraulic Climbing Formwork Applications

Applications in Modern High-Rise Construction

Automatic hydraulic climbing formwork systems have revolutionized construction practices for various types of structures:

Core and shear walls – vertical continuity and precision alignment improve structural integrity

Facade walls – self-climbing systems provide safer and faster installation

Bridge towers and signal towers – modular platforms support specialized operations at height

Silos and massive columns – enclosed environments reduce risks during material handling and concrete pouring

These systems are particularly valuable for projects with repetitive structural layouts, where traditional formwork would require extensive labor and crane operations.

Operating Conditions for GETO Climbing Formwork

Proper operating conditions are critical for safety and performance:

- Avoid construction during severe weather conditions, including thunderstorms, rain, snow, fog, frost, haze, or hail

- Basic wind pressure should not exceed level 5 (approximately 24.5–28.5 m/s)

- For wind speeds above level 7 (approximately 13.9–17.1 m/s), typhoon reinforcement measures must be applied

Adhering to these guidelines ensures that the automatic hydraulic climbing formwork system operates smoothly while maintaining the highest safety standards.

GETO Automatic Hydraulic Climbing Formwork System

Choosing the Right System for Your Project

Selecting an automatic hydraulic climbing formwork system depends on project scale, structural type, and safety requirements. GETO offers complete one-stop formwork & scaffolding solutions for global clients, providing systems designed to meet the unique demands of high-rise and large-structure construction.

GETO GTP100 climbing formwork system’s combination of hydraulic climbing, integrated platforms, and modular components ensures reliable performance, reduced labor costs, and enhanced safety. By adopting such systems, construction companies can streamline operations while maintaining quality and compliance with international standards.

Conclusion

Automatic hydraulic climbing formwork is redefining high-rise construction by combining efficiency, safety, and cost-effectiveness. GETO’s GTP100 automatic hydraulic climbing formwork system exemplifies these qualities through its integrated climbing brackets, hydraulic drive, and modular platforms.

For contractors looking to optimize high-rise construction processes, investing in a climbing formwork system provides measurable benefits in speed, labor reduction, and worker safety. GETO’s experience and technical expertise make it a trusted partner for delivering reliable, high-performance formwork solutions worldwide. Please feel free to contact us at geto_market@geto.com.cn for more information!